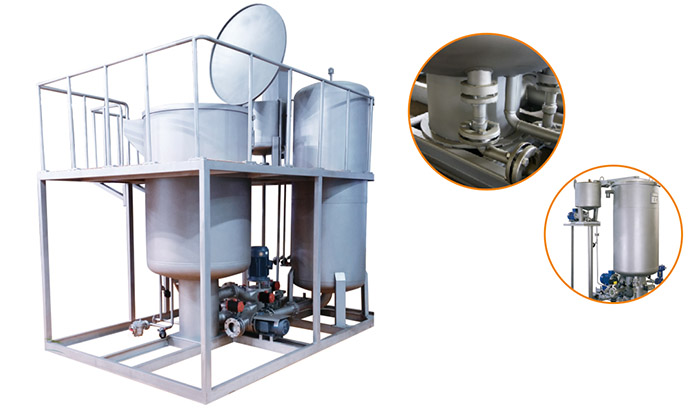

GXY (HB) HS series normal temperature and atmospheric pressure dyeing machine is suitable for dyeing natural wool. Such as: cotton, linen, silk, wool and other loose yarn, can also be used as a drifting processing. The patent design of the balance type mixed flow pump is changed automatically and penetrated into each part of the yarn to achieve uniform dyeing.

Standard structure:

The vertical cylinder structure is equipped with a heavy hammer switchgear.

The fixed device is equipped with movable plate sarong, and is equipped with an adjusting pad.

Efficient balanced type mixed flow pump, the motor is equipped with stainless steel cover and a pedestal, mounted on the bottom of the vat.

Steam coil placed at the bottom of the VAT, increase the heat exchange efficiency.

The overflow washing device can shorten the dyeing time.

Heating automatic control system.

It is equipped with 1:1 preparation cylinder to shorten the dyeing time.

It is equipped with a separate stainless steel dyeing platform.

Characteristic:

The vertical vortex pump design, can be directly installed in the bottom of the VAT, dyeing fiber density is 0.15-0.32Kg/cm, actual water consumption of 1 tons of fiber 45 tons of water consumption: 10-.

The main pump - wall filter design, can control the circulating flow and time, dyeing effect is better.

The main pump is used with the frequency conversion motor, and the required flow can be selected according to the density of the fiber, so as to achieve the perfect effect.

Using the temperature controller according to the dyeing process control, to ensure its accuracy, eliminating the use of manual control of dyeing quality problems caused by the poor.

- equipped with hand wheel type automatic tracking sarong lid lock can be prevented in the dyeing process of dye colored run by short circuit problem.

Direct or indirect steam heating.

Process data

Capacity

capacity

|

Varieties

Items

|

Working capacity

Working capacity

|

Work efficiency Work efficiency

|

實際工藝Actual process

|

Water consumption

|

Working time

|

100KGS Model

|

Acryli

|

250KG

|

2-2.5T water / cylinder times water/cylindrX4

|

<10 ton

|

2-2.5T hours/cylinder

|

Viscos

|

200KG

|

7.5T water/cylindrX5

|

<38 ton

|

5-5.5T

hours/cylinder

|

Cotton

|

180KG

|

7.5T water/cylindrX5.5

|

<44 ton

|

5-5.5T

hours/cylinder

|

|

| Specifications |

| |

|

Model

|

Load capacity

|

Main pum power

|

Dimensions(mm)

|

|

KG

|

KW

|

Master cylinder diameter

|

Height

|

|

GXY(HB)HS-50

|

50

|

5.5

|

850mm

|

4

|

|

GXY(HB)HS-100

|

100

|

7.5

|

1150mm

|

3880

|

|

GXY(HB)HS-200

|

200

|

11

|

1300mm

|

4690

|

|

GXY(HB)HS-300

|

300

|

15

|

1400mm

|

4700

|

|

GXY(HB)HS-500

|

500

|

30

|

1700mm

|

5500

|

|

| |